More About Dust Extractors For Small Workshops

Wiki Article

Facts About Dust Extractors For Small Workshops Revealed

Table of ContentsDust Extractors For Small Workshops Fundamentals ExplainedThe Facts About Dust Extractors For Small Workshops UncoveredHow Dust Extractors For Small Workshops can Save You Time, Stress, and Money.The Single Strategy To Use For Dust Extractors For Small Workshops

The obstacles for foundry dirt collection systems revolve around crystalline silica dirt, carbon monoxide gas, as well as heat, which are toxic combinations. These elements make conference air high quality requirements tough and demanding. For that reason, when choosing a dirt control system for a shop, the first consideration is the ability of the unit to withstand extreme and also unsafe work environment problems.

Covering, or thermal spray, uses heated product to steels to coat their surfaces. Dirt collection systems for this kind of procedure have to be particularly created to fit the kind of covering being applied. The purpose of the system is to regulate and reduce overspray as well as dust. The regular thermal spray dust control system uses ducts to relocate air to the collection device. dust extractors for small workshops.

Though presumably likely to increase airflow and also activity, this sort of option may mishandle and waste energy. The design of the cubicle depends upon the force of the air entering the cell or booth. For the majority of systems, it is essential to have a small vacuum in the booth to avoid feasible favorable stress.

5 Easy Facts About Dust Extractors For Small Workshops Shown

One more technique is merely placing the make-up air connection on the top of the cubicle. Regardless of the design, it is very important for the cleaning of the air to have cross air flow. Just like a cleanroom, air movement in a thermal spray booth can be either horizontal or downward, though the downward layout is best for dirt collection systems.The pharmaceutical market is a highly controlled sector with extensive as well as exact regulations. Dust from pharmaceuticals is produced mostly throughout the manufacturing as well as product packaging of items. Each step of creating a medicine, which includes granulating, drying out, mixing, pressing, finishing, and grinding, creates huge amounts of dust that need to be gotten rid of.

Obstructing and controlling this dissemination is the feature of the dust control system. When designing a dirt control system for a pharmaceutical plant, the very first consideration is mapping the ventilation system to track the path of dust, fumes, existing air movement patterns, and also feasible evolutionary adjustments. Since several pharmaceutical dusts are combustible, the design of the ventilation system is exceptionally essential.

HEPA filters are commonly found in pharmaceutical dirt control systems considering that they are one of the most effective and trustworthy. Just like a factory system, they are mounted as a secondary security to accomplish no emissions. Reusing produces a good deal of dust as an all-natural outcome of lessening items to find their raw products.

The Best Strategy To Use For Dust Extractors For Small Workshops

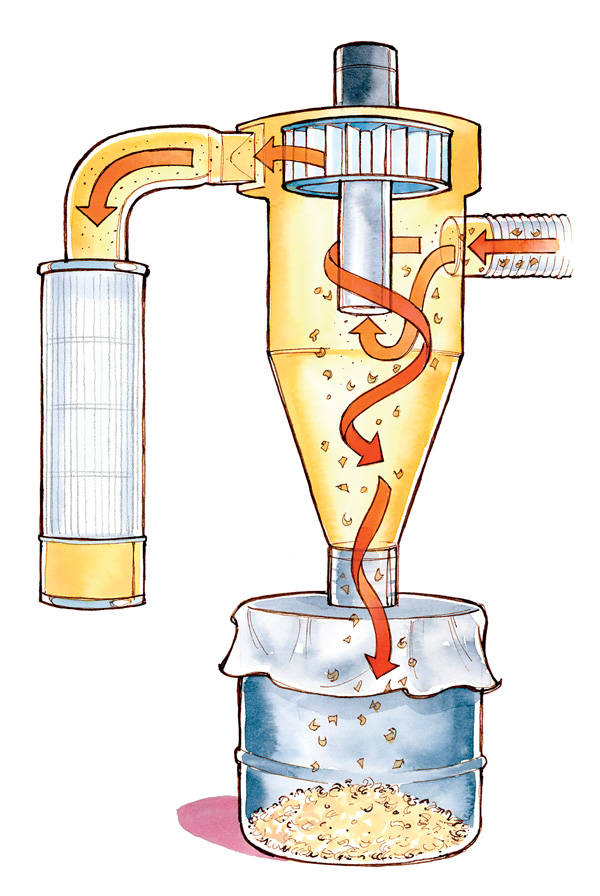

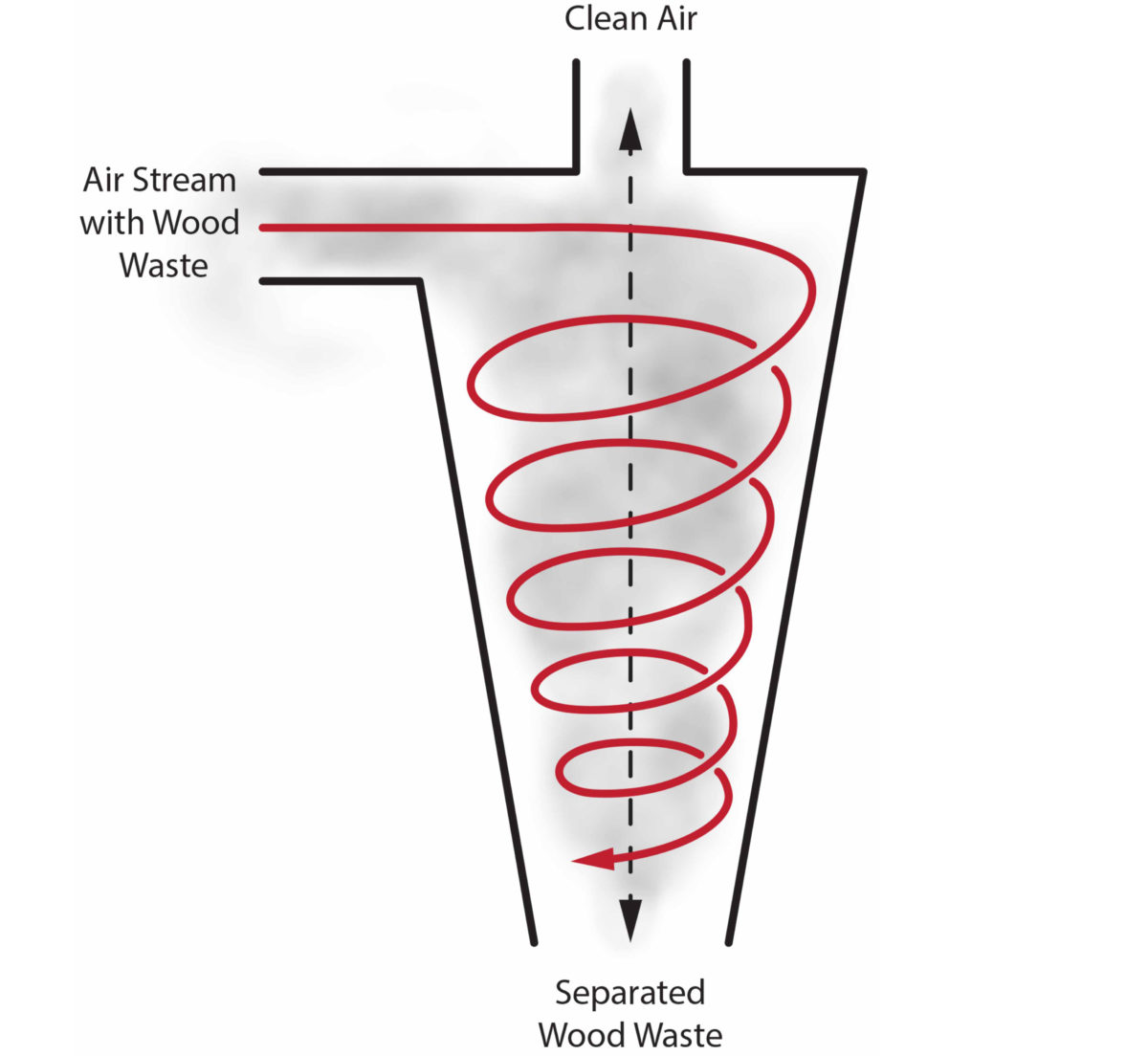

Dirt stems after products are shredded, squashed, or have paint or lacquer got rid of. All reusing centers are required to comply with air high quality standards. As they work to meet high quality criteria and also control toxins, they have actually recognized that dust control is a major issue, resulting in the vast use dirt collection systems to reduce as well as include the problem. dust extractors for small workshops.When you could check here suppliers select a dust control system, they are recommended by producers about the kind of system that would best fit their requirements since acquiring as well as mounting a dirt control system is a major financial investment. Particle matter is available in a wide range of types, from silicon dust to wood chips and also sawdust.

All about Dust Extractors For Small Workshops

Material filter bags in a cartridge system are the most effective technique for accumulating dust. Cement Concrete dirt is developed during the movement and transport of the product. Dust collection systems are covered to include the dust and also clean the air. Clay Clay dust is created in the manufacturing of bricks.Plastic Dust High-Density Polyethylene (HDPE) dirt is generated in the production of plastic panels when they are shaped and based on an continue reading this edge leaner, grinder, or miter saw. Paper Dust Among the extra usual forms of dust is paper dirt, the side result of the production of numerous types of paper.

With the introduction of dirt collection systems, workers are much safer and also much more protected. Sugar Sugar dust is the byproduct of the manufacturing of sweet. Pulse jet systems are made use of to keep the filters of the dust collection system particulate-free. The accumulated material is eliminated as well as gathered in drums. Zinc Zinc dirt is generated in the galvanizing procedure.

Rice Dirt Rice dirt has very fine as well as minute fragments that accumulate throughout the production of rice-based items. A dirt collection system is needed for the protection as well as safety of employees.

Report this wiki page